With its small-sized PCB, the Raspberry Pi can easily be protected by many types of cases. Here I show how to build a Raspberry Pi into a mini-ITX tower.

Table of contents

Introduction

The Raspberry Pi is small enough to fit into any PC tower or case, even a mini-ITX. The screw holes of the case can be used to mount the board onto many types of services and the PSU can be used to supply power to the Raspberry Pi. With some minor adjustments, switches and cable holes can be made.

For a quick reference, see the video on my YouTube channel here:

The idea behind the build was simple. I had an old ITX tower and an old Raspberry Pi lying around. The tower already had a mounting plate attached, which would make it easy to use as a media centre mounted to the existing wall bracket.

The tower used was a CFi ACD2 with a built-in 60 Watt power supply (PSU).

As far as my research goes, the CFi ACD2 mini-ITX tower has unfortunately been discontinued. For other mini or micro PC cases, a similar workflow can be followed.

- Get the Raspberry Pi 4B 4GB Starter Kit from Amazon.com

- Get the Raspberry Pi 4B 8GB Starter Kit from Amazon.com

Clearing the old case

The first step was to remove all the old PC parts from the case. Everything except the PSU and the wires was removed for now.

Wiring

When it came to the wiring, there were two important sets of wires to isolate and keep: those being used as the switch and those supplying power to the Raspberry Pi.

Wiring the on-off switch of the PSU

Firstly, the PSU needs to be able to switch on. Since we have no motherboard and its switches to work with anymore, an alternative way needed to be used. As with all PSUs, it can be switched on by bridging the PS_ON wire with ground (COM). These two wires are usually green and black.

A simple breadboard connector wire can be used to bridge these two wires directly on the connector. Many people have done this using a simple wire or even a paperclip.

Bridging wires on PSU plug using a breadboard connector. In this case, the green wire was bridged with the black wire next to it.

By supplying power to the PSU while the PS_ON and COM wires are bridged, the PSU should switch on. These two wires will later be connected by using an on-off switch (see later).

Powering the Raspberry Pi using a PSU

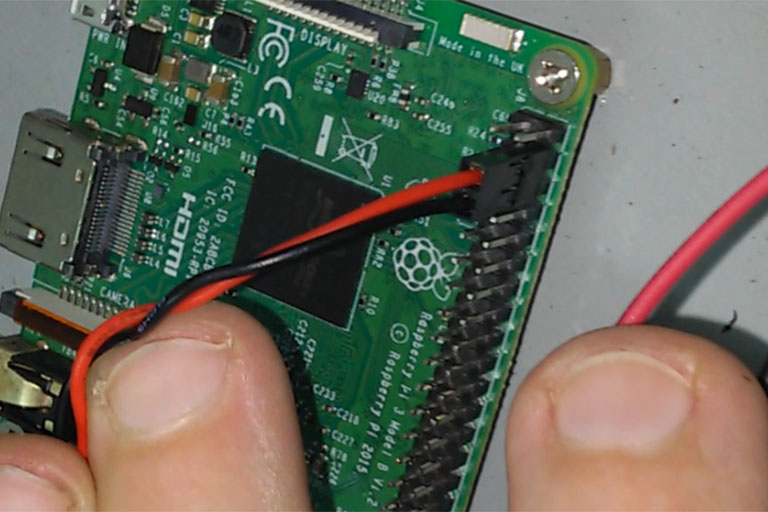

The PSU can also be used to power the Raspberry Pi. Although there are probably much safer ways described on the internet, I used a direct 5V connection from the PSU and pinned it to the power line of the GPIO.

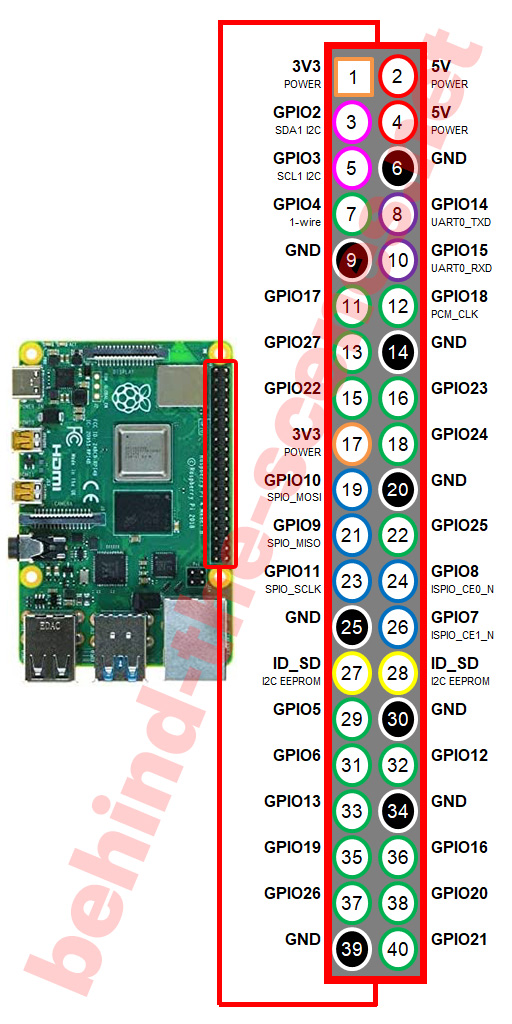

Using the GPIO to power a Raspberry Pi. The 5V (red wire) needs to be connected to pin 4 and the ground wire (black) to pin 6.

The Raspberry Pi 2/3/4 needs 5V (and preferably at least 2.5A) to power on. By testing one of the 5V lines of the PSU, by connecting a red and black wire with the DC voltage setting on the multimeter, the exact amount of voltage can be determined. The Rasberry Pi can safely take up to 5.25V DC.

By looking at the GPIO pins on the Raspberry Pi, power can be connected to pins 2 and 4. Ground can be connected to multiple pins including pin 6. I used pins 4 and 6 because they were next to each other.

By connecting power directly to the GPIO pins, the built-in power protection mechanisms (e.g. voltage regulation and fuse protection) are bypassed, meaning that over-voltage or current spikes can damage the Raspberry Pi.

Safer ways of powering the Raspberry are by using the power adaptor (micro USB port) and the appropriate connection points on the back of the board. Both these offer protected inputs. With a bit of know-how and limitations, USB ports can also be used.

- Get the Male To Female Jumper Cables from Amazon.com or BangGood

- Get the Male To Male Jumper Cables from Amazon.com or BangGood

Connecting a switch to the PSU

A simple switch for the PSU can be created using the green and black wires isolated earlier. This switch can be used to turn on the power supply when it is already connected to power. Bridging the PS_ON and COM wires is a cool trick when using an isolated PSU too.

I used 22-18AWG (red) female spade wire terminal connectors and a single-pole single-throw switch (SPST).

Mounting the Raspberry Pi to the chassis

To secure the Raspberry Pi board and to prevent contacts from touching the case, the board can be mounted onto the chassis of the tower. One can go about this in many ways, e.g. using hot glue, but I wanted a strong, non-permanent way to be able to dismantle the setup at a later stage.

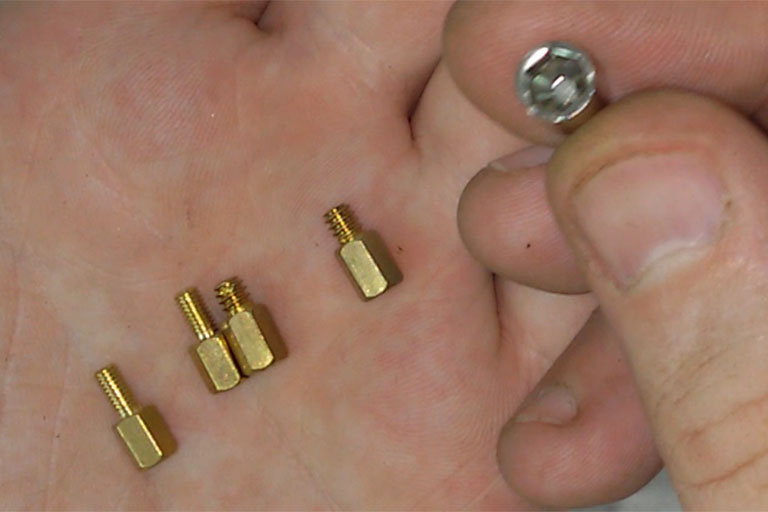

Using standoff spacers with the Raspberry Pi

For this purpose, I used some standard hexagonal male-female PC standoff spacers that were lying around. The Raspberry Pi board was screwed onto the spacers through its mounting holes after they were mounted to the chassis.

The 4 PCB mounting holes on a Raspberry Pi board are 2.5mm in diameter. This means the screw part (male threads) of the standoff spacers need to be M2.5 for the female (inner) threads to be 2.5mm in diameter too. The length of the body of the standoff spacers could have been anything that fits the height of the case, but the ones I used were 6mm high.

The spacers I used were made from brass, but plastic, aluminium or nylon spacers can also be used.

M2.5 (2.5mm) and M3 (3mm) standoff spacers. Make sure to use the correct thread thickness to fit the mounting holes of the Raspberry Pi board. Some spacer sets also include a hex screw bit (on the far right).

Drilling holes

To drill the hole in the correct place I used an old piece of cardboard as a template. Before the holes are drilled, it should be noted that the Raspberry Pi should be mounted in a way to allow enough space for the HDMI cable and the USB ports to be inserted. The drill bit needs to be able to drill metal and be 2.5mm in diameter.

Creating a side panel

To end things off, I decided to make a side panel that will hold the switch and secure the HDMI cable. By closing the side off, less dust will also be able to enter the case.

There are, once again, many ways going about creating something like this. I decided to go with a 3D-printed solution. Measurements were taken of the chassis, the HDMI cable, and the switch. Tinkercad was used to design two simple side panels.

The panels were printed using my Tevo Tarantula 3D printer using white PLA filament.

End result and final thoughts

I was fairly happy with the overall build. The Raspberry Pi was working fine and the case fitted in nicely next to the TV it was connected to. The only thing I could have done better was tweaking the side panels to cover the entire side of the case.

If there is anything you would have done differently, or there is anything that is not discussed clearly in this post, make sure to tell us in the comment section below.

Conclusion

The Raspberry Pi is small enough to fit into any PC tower or case, even a mini-ITX. Here we showed how I built a Raspberry Pi into a mini-ITX tower.